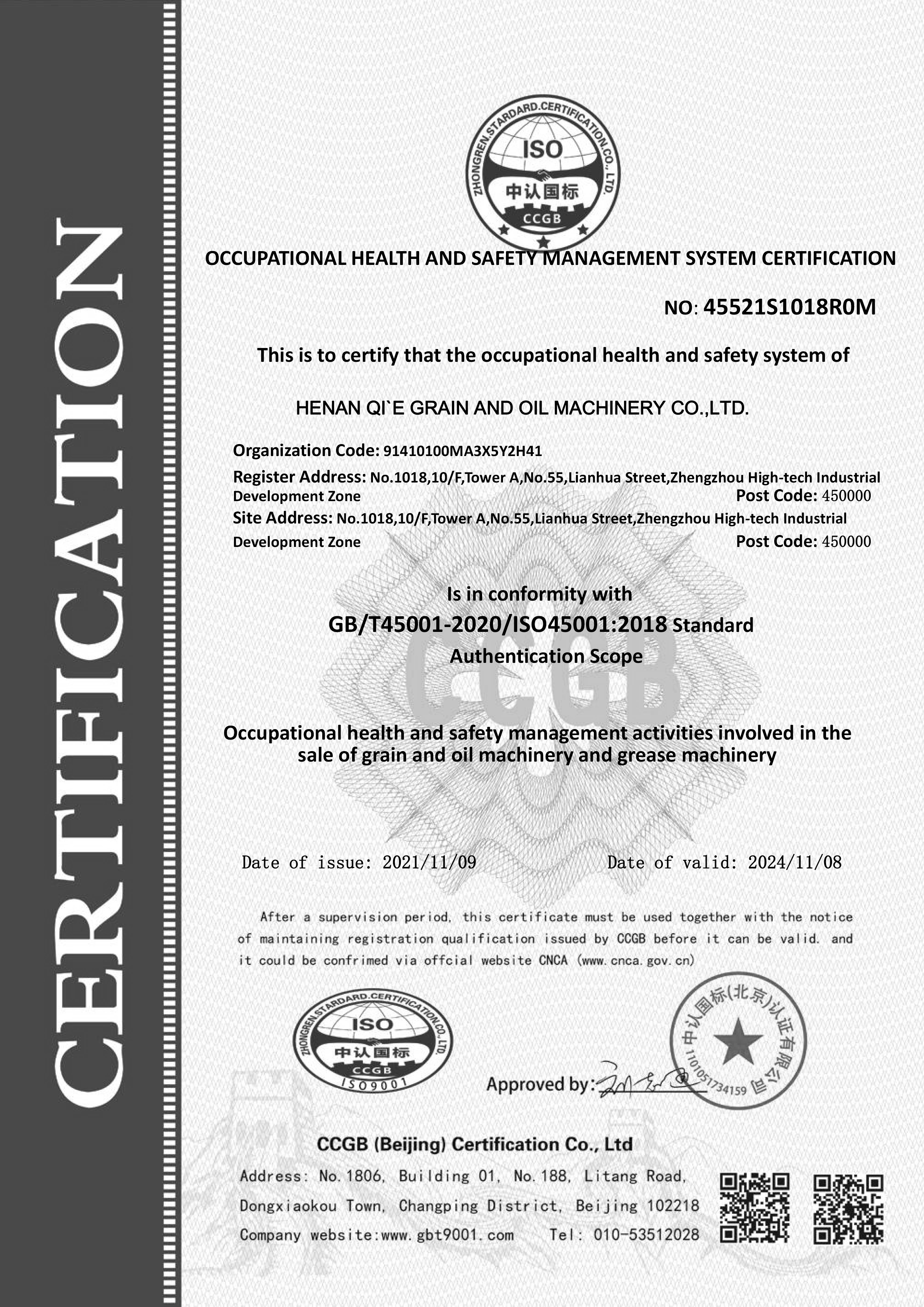

The automated palm oil pressing line is a highly efficient equipment professionally manufactured and marketed by QIE Group, mainly used for the extraction and production of palm oil. This set of equipment includes a spiral palm oil extractor, which can effectively handle production capacities from 1TPH to 40TPH, with a maximum processing capacity of up to 2,000 tons per day. The equipment features fully automated operation, using both cold and hot pressing processes to ensure high precision and low loss during the extraction process. The core components such as motors, pressure vessels, pumps, PLCs, gears, etc. are all high-quality components, and the overall quality of the equipment meets international certification standards such as ISO9001, BV, and CE. It is particularly suitable for manufacturing, food and beverage factories, and farms, and can provide customized services according to customer needs, including customized logos, packaging, and graphic design. The product has low consumption during the production process, with 5~50kg of clay consumed per ton of oil and about 450kg of steam consumed, ensuring high efficiency and environmental protection. The production line has won wide recognition in the market for its high performance and stability, and has performed particularly well in international markets such as Asia, Africa, and South America, continuously bringing high returns on investment and production safety to customers.

1. Efficient processing: The processing capacity ranges from 1TPH to 40TPH, up to 2,000 tons/day, meeting the needs of large-scale production.

2. Fully automatic operation: adopting cold and hot pressing process, high precision, low loss and easy operation.

3. High-quality components: core components such as motors, pressure vessels, pumps, PLCs, gears, etc. are made of high-quality materials to ensure equipment stability.

4. International certification: The products comply with ISO9001, BV, CE and other international standards to ensure quality and safety.

5. Environmental performance: Each ton of oil clay consumes 5-50 kg, and each ton of oil steam consumes about 450 kg, which is highly efficient and environmentally friendly.

1. Manufacturing: Suitable for large-scale palm oil extraction and production.

2. Food and beverage factories: ensure efficient production of food-grade oils and fats.

3. Farm: Suitable for oil processing needs of medium and large farms.

.png)